Mechanical Actuators

Sliding Control Cables

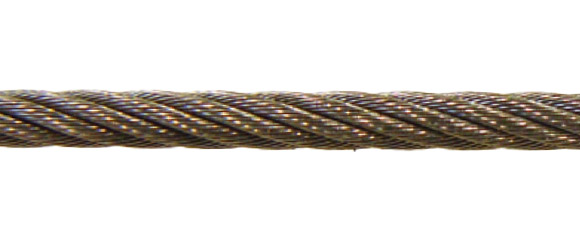

Sliding controls cables are push/pull assemblies composed of an internal core and external conduit. The core is typically made up of woven wire strands that operate within an enclosed conduit. The application or installation and the materials of construction determine the operating characteristics of these controls (efficiency, backlash, load and bend radii).

Characteristics

AeroControlex sliding controls are designed to suit individual applications and custom configurations. A wide variety of sizes and accessories are available.

Sliding controls have high load carrying capabilities and are very robust, but generally less efficient than ball bearing controls. They derive their name from the linear “sliding” motion of the core within the conduit.

Typically, sliding controls are characterized by less stringent efficiency and backlash requirements. Light or heavy loads, highly configured, small in size, rigid conduits, field replaceable cores, flexible races and tension only loaded applications favor sliding controls.

Typical Applications

- Engine Feedback Controls

- Girt Bar Controls

- Passenger Entry Door and Mode Select Controls

- Lavatory Drain Controls

- Thrust Reverser Controls

- Speed Brake Controls

- Emergency Exit Door Controls

- Pitch and Roll Disconnect Controls

- Emergency Controls

- Tension Only controls

Product Features

- Transmission of linear and/or rotary motion

- High load carrying capability

- Installation flexibility for routing in complex layouts

- High reliability and low maintenance

- Operation in extreme temperature and atmospheric conditions

- Patented sealing features prevent debris / fluids from affecting control’s performance.

Typical Sliding Control Cables Construction

AeroControlex sliding control consists of a core element and an outer conduit. The core is available in numerous sizes, materials and constructions to meet the requirements of the individual applications. The outer conduit is also available in numerous sizes and construction to house the inner core and to meet the characteristics of each installation.

AeroControlex sliding controls are designed and manufactured to high-performance specifications to balance low friction and minima backlash characteristics. AeroControlex is equipped to design and manufacture custom sliding controls to meet individual application requirements.

Core Types

Single Strand or Multiple Wire

Features:

- Lower cost

- Small envelope

- High tension capability

Flat Wrap

Features:

- Tension and compression capability

- Higher efficiency through lower friction

- Less susceptibility to performance variations

Helical Wrap

Features:

- Provides linear to rotary motion translation

- Acts as a flexible rack when used with a hobbed wheel

- Allows for repairable or replaceable core

Conduit Types

Long Lay

Features:

- Good flexibility

- High Strength

- Contamination and abrasion resistant

Long Lay With Roving Wrap

Features:

- Adequate flexibility

- High Strength in tension and compression

- Can be contamination and abrasion resistant with polymeric cover

Rigid Tube Conduits

Features:

- Small envelope

- High Strength / Robust assemblies

- High temperature capability

- Contamination and abrasion resistant

Monocoil Conduits

Features:

- High flexibility

- High compression load capability

- High temperature capability